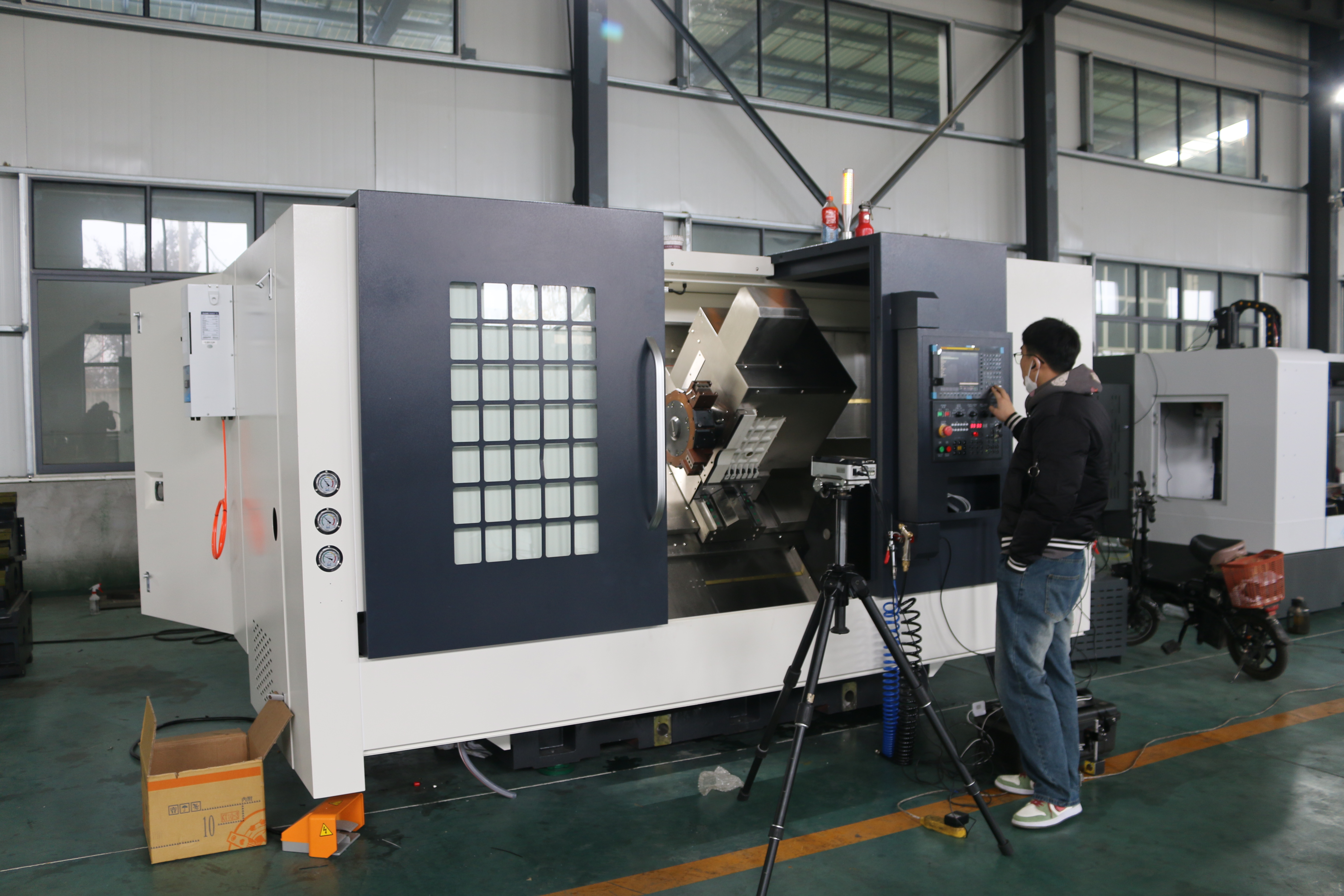

TCK700

The machine tool is suitable for automobile, motorcycle, electronics, aerospace, military, petroleum and other industries. It is capable of automatic machining of conical surfaces, arc surfaces, threaded surfaces and all kinds of imperial threads.

The spindle is close to the center of the manipulator, which is convenient for loading and unloading workpieces. The guide rail adopts imported linear roller guide, with improved feeding precision, low friction resistance, good rigidity, and strong anti-vibration and deformation ability, which allows users to obtain higher machining precision, improve the speed of rapid movement, and obtain higher production efficiency.

The machine tool is suitable for automobile, motorcycle, electronics, aerospace, military, petroleum and other industries. It is capable of automatic machining of conical surfaces, arc surfaces, threaded surfaces and all kinds of imperial threads.

The spindle is close to the center of the manipulator, which is convenient for loading and unloading workpieces. The guide rail adopts imported linear roller guide, with improved feeding precision, low friction resistance, good rigidity, and strong anti-vibration and deformation ability, which allows users to obtain higher machining precision, improve the speed of rapid movement, and obtain higher production efficiency.

Applications:

The machine tool is suitable for automobile, motorcycle, electronics, aerospace, military, petroleum and other industries. It is capable of automatic machining of conical surfaces, arc surfaces, threaded surfaces and all kinds of imperial threads.

The spindle is close to the center of the manipulator, which is convenient for loading and unloading workpieces. The guide rail adopts imported linear roller guide, with improved feeding precision, low friction resistance, good rigidity, and strong anti-vibration and deformation ability, which allows users to obtain higher machining precision, improve the speed of rapid movement, and obtain higher production efficiency.

Specificities:

·Highest precision Taiwan linear guideway

·High-speed spindle unit, optional self-made spindle

·High hardness cast iron

·Integrated automatic lubrication

·Integral casting inclined bed CNC lathe

Standard Configuration:

·Fanuc 0i TF+15-inch touch screen

·18.5/26kw motor

·12-station BMT55 power turret

·10-inch hydraulic chuck

·A2-8 spindle

·Renishaw tool setting instrument

·Programmable tailstock

·Center frame 20-165mm

·Automatic cooling system

·Automatic lubrication system

·Full protection

·Three-color warning light

·Tool box

Product Parameters:

Number of controlled axes of the CNC machine (numerical control) 4 (X, Y, Z, C)

Maximum travel along the X axis, mm 260

Maximum travel along the Y axis, mm 120 (±60)

Maximum travel along the Z axis, mm 1500

Maximum travel speed along the X axis, m/min 20

Maximum travel speed along the Z axis, m/min 24

Maximum travel speed along the Y axis, m/min 10

X/Z positioning accuracy, mm 0.01/0.02

Accuracy parameters according to JIS B 6338, VDI/DGQ3441.

X/Z positioning repeatability (full stroke), mm, in the range ±0.002 / ±0.003

Guide type sliding

Turret head type BMT 65

Number of positions in the turret head, pcs. 12

Tool size in the turret head, cross-section of the tool holder, mm 25x25

Tool size in the turret head, cylindrical cross-section of the tool holder, mm Ø50

Turret indexing time, sec, in the range 0.25

Bed material Hardened cast iron

Bed construction Solid cast

Bed tilt angle, (degrees) 45°

Maximum turning length, mm 1250

Maximum turning diameter, mm 650

Maximum turning diameter over bed, mm 700

Maximum turning diameter over support, mm 500

Diameter of three-jaw hydraulic chuck, mm (inches) 305 (12”)

Spindle drive type belt

Spindle taper (ASA) A 2 - 11

Spindle bore diameter, mm 105

Maximum spindle rotation speed, rpm 2500

Maximum torque on the main spindle, Nm 1050

Continuous torque on the main spindle, Nm 670

Maximum spindle drive power, kW (15 minutes) 22

Continuous spindle drive power, kW 18.5

Milling function drive tool power, kW 5.5/3.7

Torque of the milling function drive tool, Nm 70/35.4

Maximum speed of the drive tool, rpm 5000

Presence of a tailstock

Diameter of the tailstock quill, mm 100

Quill taper, MT 5

Tailstock quill travel, mm 100

Tailstock travel, mm 1300

CNC-controlled hydraulic steady rest (including programmable base and bracket for mounting the steady rest), mm Ø50-200

BDEFU hydraulic collet chuck for clamping parts by inner diameter

BDEFU No. 4 1 pc

BDEFU No. 5 1 pc

BDEFU No. 7 1 pc

Set of non-hardened cams 12", pcs. 4

Set of hardened cams 12", pcs. 2

Axial milling head, pcs. 3

Radial milling head, pcs. 3

Capacity of the tank for lubricating and cooling fluid ZOR, l 200

Light signaling of machine operating modes (3-color signal lamp)

Length, mm 4500

Width, mm 2200

Height, mm 2200

Weight, kg 8800

FANUC Oi-TF Plus CNC (computer numerical control) system

Diagonal color touch screen of the CNC (computer numerical control) rack (inches) 15”

Data server 1GB data storage device

English version with an authentic Ukrainian translation of the interface in paper form

Variable spindle speed to prevent vibrations

Graphical simulation of the machining trajectory on the CNC (computer numerical control) screen of the next part during machining

Availability of a program for graphical visualization of processing on the CNC (computer numerical control) stand

Availability of standard cycles for turning, boring, thread cutting, processing of curved surfaces, drilling

Availability of handwheels for manual movement along the machine axes (X, Z, Y)

availability of a switch for discrete movement along the machine axes, mm X, Z: 0.001/0.01/0.1

presence of a place for zeroing on devices under voltage 380V and 220V, 50Hz

presence of adjustable spindle and axis drives

presence of power indication for the main motor

presence of a backup copy of the machine's electrical automation program with comments for PLC in electronic form

presence of a full-size industrial keyboard

presence of control program (CP) input and output from the system console, USB, Ethernet

presence of a licensed CAM (Computer-aided manufacturing) system with unlimited term of use, for operation on all axes with a post-processor.

the ability to start processing from any frame of the program

the availability of lighting in the working area

the availability of a machine safety switch

the availability of a full protective cover for the working area with protective glass for monitoring the working area

Availability of a belt conveyor for chip removal with discharge to the right side of the machine and a chip collection tank.

The presence of an internal supply system of lubricating and cooling fluid (LCF) through the axial tool, with a pressure of 6 bar.

A centralized lubrication system for guides with consistent grease

Automatic tool binding

Data Server Interface

Interface for accessing the data server from external devices

Arbitrary speed threading function

For the operator to adjust the spindle speed during thread cutting to control vibration. Re-processing of thread threads.

Constant cutting speed processing function

Tool load detection function

Tool life and load monitoring function

Warranty period from the date of delivery: 24 months.

Product Description

FAQ

1: Where is your company

A: Our company is located in Tengzhou City, Shandong Province.

2: What about your warranty?

A: Warranty is one year. During warranty time, if the parts are damaged because of Nonhuman factors, we will send new replaced parts for free

3: How do you offer after-sale service?

A: We usually offer technical support online by wechat or whatsapp. Customer describe the problems and send videos and pictures, our technician will help to solve the problems

4. What is your standard package?

A: Our package is export standard plywood case with pallet.

5: What's the Payment Terms?

A: T/T, 30% initial payment when order, 70% balance payment before shipment;

6: What's the MOQ?

A: 1 set.

PHONE